Methodology

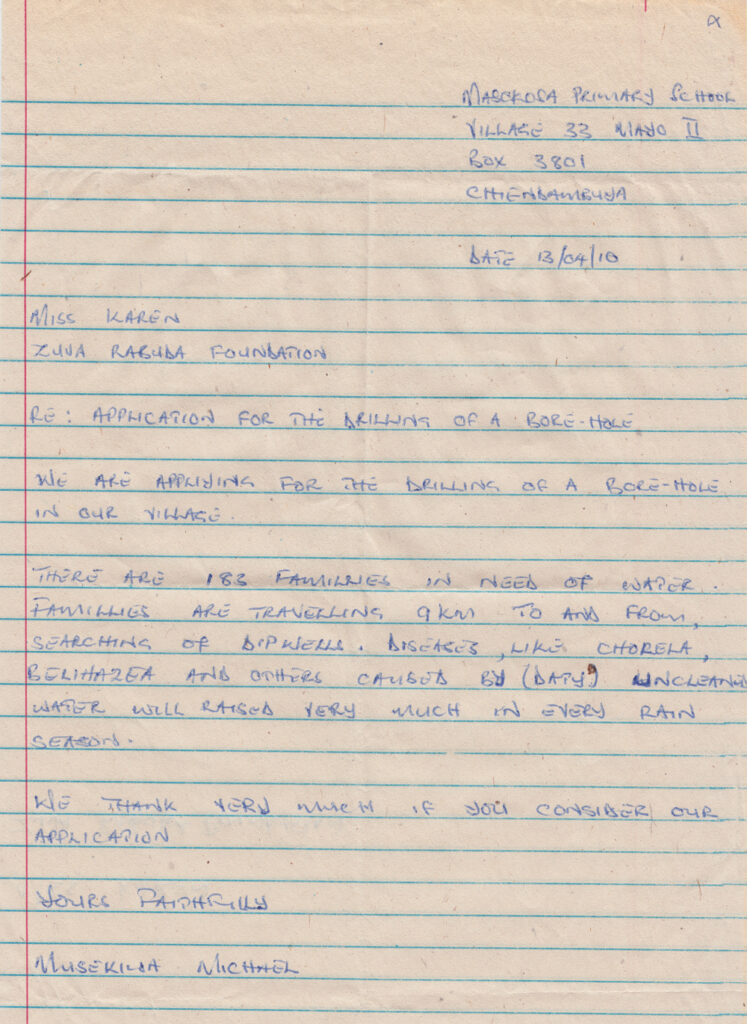

Village leaders send us direct requests for boreholes. You can see an example of such a letter here. Together with residents and experts, we determine which villages qualify for help. In Zimbabwe by the way a well is a water source digged by people so not really deep. A borehole is a drilled hole.

With the help of a water locator or geofysicus in Zimbabwe, we search the village for places where water may be present underground. He also tells us how deep we have to drill.

The residents must then build their own road to the “waterspot.” This is because the drilling company drills boreholes with a compressor. The compressor and the drilling equipment together weigh 8,000 kilograms. The main roads in the areas are unpaved. The whole thing can pass over those. However, the side roads are often much too narrow (suitable only for donkey and wagon), branches hang too low, there are large potholes in the road, etc. Sometimes to the respective spots there are only footpaths. Of course, residents are given instructions regarding the construction of roads. Villagers are responsible for this themselves under the motto “ no road, no borehole”.

The drilling company is based in the capital city of Harare and operates a state-of-the-art machine. In a few hours, the company drills right through all kinds of rock. Tension always runs high when drilling. Is there water or not? So the discharge is great when water is found. It remains a spectacular sight when the water squirts out!

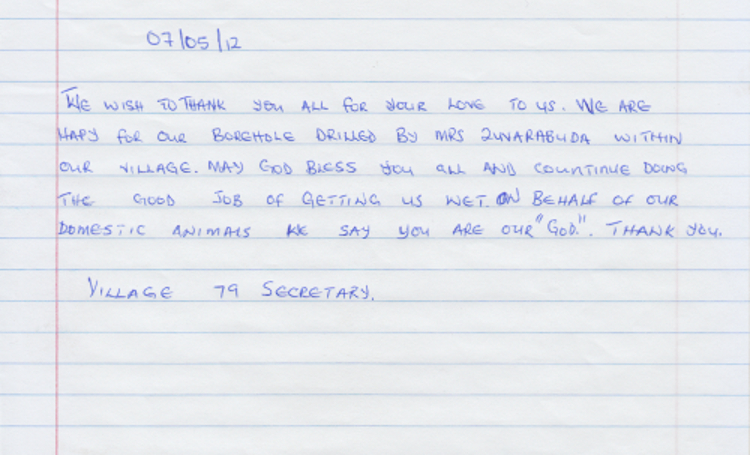

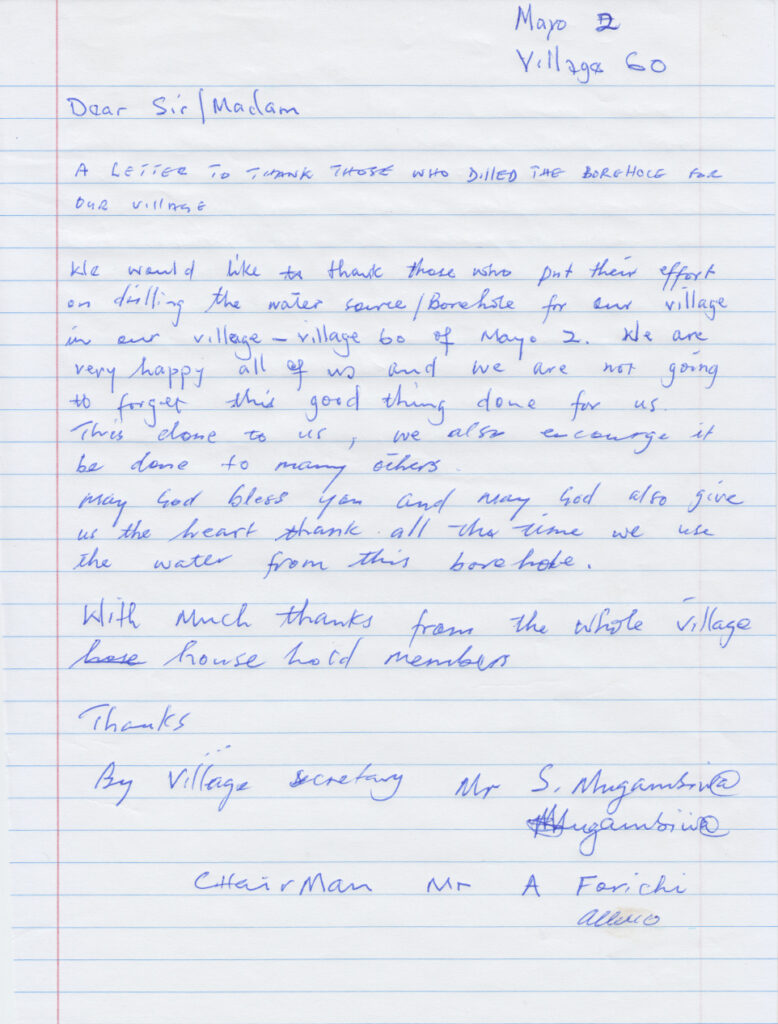

The thank you letters from the villages express the joy well. You can see an example here. In the borehole comes a PVC pipe that ensures that the borehole does not collapse. A lid seals the hole.

When water is found, residents contribute a one-time US$2 per household. This is to emphasize, that they themselves are responsible for the well and have contributed to it financially.

Because the water must come from very deep, sometimes 55 meters, special pumps are needed. Moreover, the maintenance of the pumps should not be too expensive and should be done by the people themselves. So-called “rope” pumps meet these requirements. They are suitable for fetching water from great depths and are easy to maintain. A ‘rope’ pump consists, among other things, of a rope with small circles of rubber (from a car tire) and a frame of iron with a handle. Through an expert in the Netherlands, we found an organization in Tanzania that installs such pumps. An employee of this company installed the first pump for us; then trained two people from the region, who installed the remaining pumps. They also learned how to maintain the pumps.